Agricultural maintenance scaffolding

Specifications

Information

- Mobile scaffolding made of sturdy round aluminium tubing with welded frame parts

- The open platform side allows tractors, combine harvesters or other vehicles to drive directly under the scaffolding and immediately reach higher areas.

- Space-saving transport and storage

- The integrated ladder provides quick, ergonomic and completely safe access to the work platform.

- The generous work surface measuring 3.00 × 1.20 m offers maximum freedom of movement and space for tools and materials.

- All scaffolding parts are also available individually as spare or extension parts

- Folding frame made of rectangular tube side-rails with self-locking hinges

- Four Ø 125 mm swivel castors with centric load application and spindles

- Slip-resistant platform for secure standing

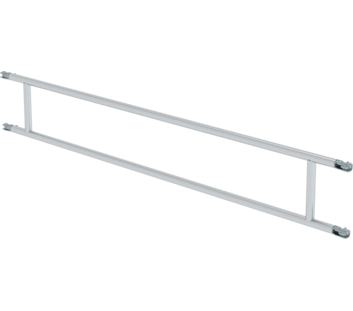

- Aluminium toe boards and railing frames with integrated knee board as safety railing (from platform height of 2.8 m and higher)

- Simple setup and removal without tools

- Different platform widths available (0.75 / 1.35 m)

- GS-tested as per DIN EN 1004

- Load class/scaffolding group 2: 1.5 kN/m²

The Agrar maintenance scaffold is a robust and practical working platform that has been specially developed for the requirements of agricultural businesses. Whether used indoors or outdoors, with a working height of up to 4.16 m and a platform height of 2.16 m, the scaffold offers ideal conditions for maintenance, cleaning and inspection work on tractors, combine harvesters, other agricultural machinery and various types of vehicles.

With a platform area of 3.00 m × 1.20 m, the scaffold offers ample space for safe working, even when tools, spare parts or cleaning materials need to be kept directly at hand. The area is dimensioned so that you can move freely and safely without having to constantly reposition yourself.

A special highlight: one side of the platform is open. This allows a vehicle to be driven so close to the scaffold that wheels, axles or even the front end can be pushed under the platform.

This allows you to easily reach higher areas such as:

- Driver's cabs

- Bonnet

- Maintenance flaps

- Air and oil filter areas

The integrated ladder provides quick, safe access without detours and without additional ladders or aids.

All components are easy to handle and designed so that the scaffold can be transported quickly, set up rapidly and adapted flexibly. Ideal for use in changing locations, whether in the yard, in the stable or in the workshop.

Self-locking scaffolding claws, which connect the frame elements firmly and permanently, ensure maximum stability.

The swivel castors with locking brakes offer a powerful combination of mobility and stability:

- easy movement of the scaffolding

- secure hold during work

- Corporate certification: ISO 9001

- Corporate certification: ISO 14001

- Corporate certification: EN 1090

- Corporate certification: EcoVadis

- RoHS

- REACH

- The MUNK Group complies with a Code of Conduct

- The Supply Chain Act does not apply due to our size

- The materials used are listed in the technical specification

- Resource-saving production: own photovoltaic systems

- Energy-efficient consumption during production: LED lighting

- Repairability, durability and quality: 15-year warranty on series products made in Germany

- Recyclability: Our products are mostly made of aluminium, steel or wood and can be fed directly into the recycling process.

- Socially acceptable working conditions in production: fair wages, gender equality

- Economical and recyclable packaging: no use of polystyrene, predominantly use of wood and cardboard, small amounts of plastic

- No health hazards for the users

Best Brand of the Year 2025 – Plus X Award

- MUNK is the only company in the access equipment industry to receive this award.

- The jury's reasoning: MUNK stands for safety, innovation and responsibility in the field of access equipment like no other brand. With excellent product quality, a strong customer focus and sustainable practices, MUNK has been setting standards for years.